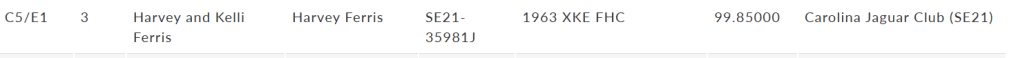

Last fall I wrote an article (#1?) regarding the ranking of my Champion class Jaguar E-Type FHC in the JCNA North American Standings. At that time my car was listed in first place for the C5/E1 class. C5/E1 is Series 1 Jaguar E-Types, both FHC and OTS. At that time, I advised a wait and see attitude, as many scores were still coming in from across the country. I think the dust has settled, so to speak. Currently my car is listed in 3rd place. A Podium Finish! My average score of 99.85 was eclipsed by what I expect are two very nice OTS (Open Two Seater) cars. The number one car is owned by Al Jacobson of the Jaguar Affiliates Group of Michigan, with an average score of 99.99667. Imagine the chagrin of Terence and Barbara Smith of the Jaguar Club of Pittsburgh, whose average score was only 99.98667! My congrats to both of these owners.

Not being one to rest on my laurels (I prefer to rest on my sofa), I have spent the last few months fussing with some nagging issues on my car. I am trying to get it ready for sale on Bring A Trailer in the spring and want it to be in top shape. (Feel free to contact me if you are interested in an advance viewing). One issue was a balky starter. I believe I have found the problem, which seems to be a poor ground connection from the body to the starter. I have added a decidedly non-original heavy cable directly from the battery cable to the block. That seems to have solved the problem. The cable is pretty much out of sight and it sures beats a car that doesn’t want to reliably crank.

In my last article, I discussed Cheney clamps. As discussed in that article, this subject was on my mind as I tracked down random coolant leaks. I would like to issue a clarification on that article. JCNA Concours rules do not specifically judge the “make” of clamps used in the engine compartment. The rules state “Hose clamps must match the original including the material, the finish, the configuration of the adjustable band, and the shape and style of the adjusting screw head. All pre-1975 hose clamps must have round head, and straight-slot adjusting screws; their adjusting bands must be grooved, not perforated. (Hexheaded clamp adjusting screws did not appear until approximately 1975.) Brand name is not judged.” So if you are able to find some clamps that meet this criteria, you are good to go.

There is another nagging issue that is bugging my wife, and therefore is bugging me. I wound up with some wrinkles in the vinyl upholstery that fills in the large space above the wheel wells and below the rear quarter windows and rear hatch trim. These were panels that I had fabricated myself, as the originals sent to me by my upholstery supplier were sized for a slightly newer model of my car. I do fault my supplier to some degree for missing this but as the error was found during Covid times and the supplier is located in the UK, I discussed it with them and we decided that it was something I could deal with. If you recall, trans-Atlantic shipping was crazy expensive at that time, due to lack of passenger plane traffic. Anyway, my brain got used to the wrinkles over time but again, they were a nagging issue. It is an unfortunate characteristic of vinyl that it does not shrink due to heat or moisture the way leather does. These panels are tough because they have a transition into a concave curve as they reach into the rear of the car. They also have a difficult trim situation around the quarter window opening. As I write this, I think I have it whipped. I have done several test pieces to perfect my technique. Another problem with my original pieces was perfecting the outside corners. I can recommend a fellow on Youtube, who goes by Checaflo, who has a number of good tutorials on automotive upholstery, including outside corners done with vinyl.

On the subject of changes to the interior upholstery, it is safe to say that it can get complicated. If you have a reasonably untouched car that you are looking to restore, you can take your cues from what you have. But if you are a stickler for “how it came from the factory”, you will have to do your research. My main research sources are the Spare Parts Catalogue and Jaguar Service and Spares Bulletins. Two good books are Jaguar E-Type Six-Cylinder Originality Guide, Dr. Thomas Haddock and Dr. Michael Mueller and Original Jaguar E-Type, Malcom McKay. For the early FHCs, be aware in particular of the following Spare Parts Bulletins (SPBs). The P series generally addresses changes to the interior.

P.51- Introduced the heel wells in the floors (FHC and OTS), June 62.

P.55- Introduced seat belt anchors, April 62.

P.60- This is a big one, as it revised almost every part on the FHC, June 62.

P.61- Added the dished bulkheads behind the seats, June 62.

P.71- Introduced interior aluminum panels with a “cross hatch pattern”, November 62.

P.78- Revised the luggage mat, April 63.

P.79- Numerous changes to the interior configuration, April 63.

P.84- Revised the grab handle, May 63.

P.86- Revised the trim on the doors, June 63.

Well, you get the idea. My car was built on January 2nd, 1963. There are over 1000 Service and Spares Bulletins for the Series 1 cars alone. I subscribe to the Coventry Foundation Bulletin Database Service. This service has been invaluable. If you have any particular questions about your restoration, feel free to contact me.

Discussion

Comments are closed.