As some of you may know, SNG Barratt is a major supplier of parts for all manner of Jaguar cars. SNG Barratt was established in 1982 by Stephen Barratt. He was an avid enthusiast of classic cars, Jaguar in particular. He saw a need for quality replacement and repair parts for older Jaguar cars, no longer a priority of Jaguar the company. 43 years later, SNG Barratt has grown to a worldwide business that supplies thousands of bespoke parts for Jaguar and Daimler cars. SNG Barratt was recently absorbed, along with Moss Motors and Rimmer Brothers, by Radial Equity Partners. It is not official yet but I suspect that SNG Barratt will retain its identity as the preferred partner to supply parts for Jaguar cars.

When I started the restoration of my first E-Type, back in 2005, SNG Barratt quickly became my go-to supplier for restoration parts. For my most recent restoration of a 1963 E-Type FHC (which came to me in boxes) they were again my go-to source for parts. I’ve spent a lot of money with them. By and large, their parts are first rate in quality and when there are shortcomings, they are always prompt in rectifying the situation. As the years have gone by, they have developed a significant in-house manufacturing capability for the parts they sell. Let’s face it, restoration parts for classic Jaguars do not really warrant high volume manufacturing methods, where the high cost of automation is offset by millions of parts produced and sold. For many of the parts SNG Barratt sells, they make them the old fashioned way- one at a time.

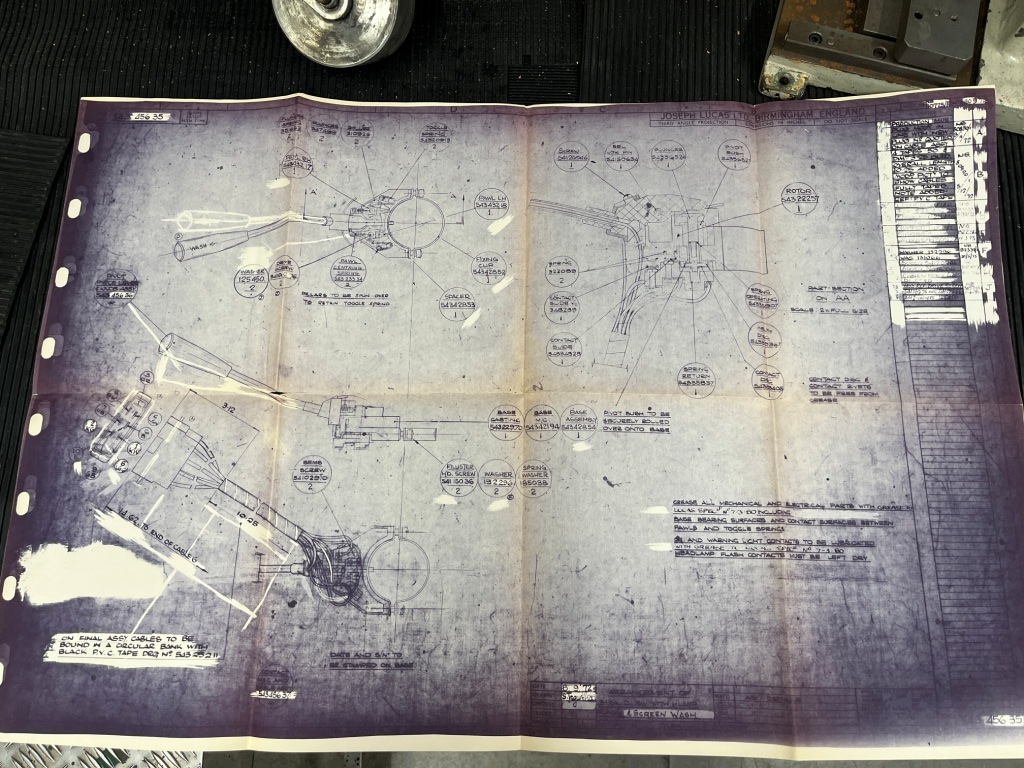

During my recent trip to the UK, I arranged for a tour of their facility in Bridgnorth, near Manchester. I was met by Julian Parker, who is the Product Manager for the Lucas line of parts. Lucas made a lot of parts for British cars in the day but at some point they ceased to be active. SNG Barratt has purchased the rights to produce exact replicas of classic Lucas parts. They have much of the Lucas technical documentation and a significant amount of the manufacturing molds, jigs, fixtures, etc. Julian has spearheaded the effort to expand SNG’s catalog of genuine Lucas parts.

The facility in Bridgnorth includes sales, warehousing, shipment, manufacturing, and quality control. SNG Barratt also has sales offices in Europe and the US. I was mainly interested in seeing the manufacturing effort. So my tour began.

As you might expect, I saw metal forming, welding, casting of metal and plastics, electrical component fabrication, and final assembly. It is a very industrial setup, just on a somewhat smaller scale compared to most “factories”. There is also a substantial R&D and testing component to the facility. For instance, they have just released a new bespoke fuel injection setup for the XK line of engines. I popped into their QC department, where I heard some of the same jargon that I was used to in my nuclear power career. SNG Barratt is ISO 9001 certified.

I took a fair number of pictures but I encourage you to check out the SNG Barratt Youtube channel. In particular, take a look at the short documentary Unforgotten Legacy, which does a nice job of capturing the spirit of the “shop floor” at SNG. Another worthwhile video is 40 Years of SNG Barratt.

After we finished our tour of SNG Barratt, Julian took me down the road to Jenvey Products. Jenvey is a small manufacturer of fuel injection and carburation products for specialty and race prepared engines. They worked with SNG to develop the above mentioned fuel injection system for the XK engine. At their facility, I saw aluminum casting, welding, and 5-axis numerical machining of parts required to assembly their line of throttle bodies, manifolds, and inlet systems. Again, a small shop with lots going on.

I know when I was younger, the term “cottage industry” was a phrase that most likely invoked folks sitting in their houses making shoes and spinning yarn to weave into clothing. I think firms like SNG Barratt and Jenvey are the modern cottage industries of this world. People coming to work and producing a product, with pride in the results of their labors. It was great to see!

Discussion

Comments are closed.